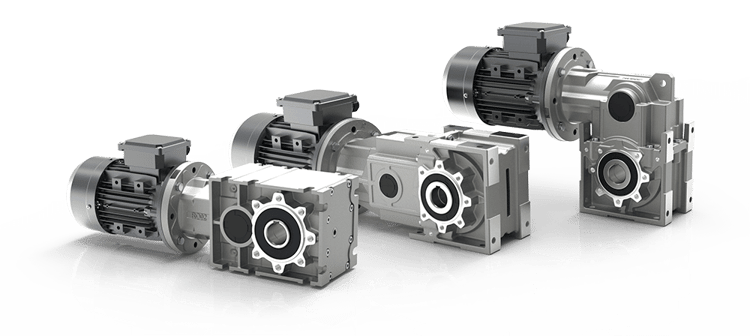

Gearboxes are crucial components in the world of mechanics and have always been so. Their success is in their usefulness.

There is a gearbox in the heart of every movement. Like all vital components of a machine, everything – from the internal components to the exterior paintwork – must be manufactured to the highest quality standards. As part of our continual improvement process, we have recently updated and expanded our offering of high-quality surface protection for VARVEL gearboxes. The characteristics of our coatings are illustrated below:

Standard paint for cast iron gearboxes

Epoxy powder paint on unassembled raw and semi-finished components made of cast iron. More in detail, the epoxy-resin-based thermosetting powders are particularly suited for their thermal stability and have excellent anti-corrosion properties.

- Thickness: 60 / 120 μm (UNI ISO 2178-98)

- Adherence: GT0 (cross-hatch test UNI EN ISO 2409-96)

- Corrosion class: Similar to Cat. C2 according to ISO 12944-2

- Color: RAL 7012

Liquid paint for aluminum gearboxes

Consisting of one coat of two-component epoxy primer and a two-component polyurethane enamel finishing top-coat.

- Corrosion class according to ISO 12944-2

- Available thicknesses: Basic thickness 50 ... 120 μm, color RAL 7012

- Intermediate thickness 150 ... 200 μm, color RAL 9006

- Maximum thickness 220 ... 260 μm, color RAL 9006

White paint for food-processing environments (aluminum gearboxes)

Paint for food-processing environments, where there is no direct contact with foodstuff, consisting of a coat of two-component epoxy primer and two-component acrylic top-coat based on hydroxylated acrylic resins and aliphatic isocyanate adduct.

- Color: white RAL 9010

- Corrosion class: Similar to Cat. C2 according to ISO 12944-2

- Thickness: 100 – 200 µm

Black anodizing treatment for aluminum gearboxes only

Anodization is the main protective treatment of aluminum. It forms a very hard and compact aluminum oxide surface layer that increases the surface properties of corrosion resistance, wear resistance, hardness, and dielectric insulation.

UNI 10681 is the reference standard for the Varvel anodizing process.

Fluotitanation for aluminum gearboxes (only available in combination with paint)

The fluotitanation process stops the formation of corrosion and guarantees the resistance of aluminum to chemical and/or atmospheric elements. It is a surface treatment that uses a titanium-based system to create a colorless layer on the surfaces. It ensures corrosion resistance and has excellent paint adhesion properties. The process is chromium-free. Therefore, the environmental impact is lower than that of traditional products containing chromium.

- Indicative thickness 2 ... 5 μm

- Only available in combination with liquid paint:

- Intermediate thickness 150 ... 200 μm, color RAL 9006

- Maximum thickness 220 ... 260 μm, color RAL 9006

Get in touch with the Varvel experts to receive more information about our high-quality surface protection or a free personalized quotation.