Precision planetary gearboxes are also known as precision epicyclic gearboxes.

They are essential mechanical components for very many industrial operations, in the most diverse sectors. Areas of application include food and beverage, intralogistics and logistics, packaging, mechanics, and practically anywhere where a high transmission ratio is required or where there is the need to transmit torque with high RPM drives, such as servo motors.

The operating principle of a precision planetary gearbox is relatively simple. The input shaft (sun gear) drives three gears (planet gears), which in turn rotate within a fixed toothed ring, called the ring gear. The planet gears mounted on the carrier turn slower than the original speed of the sun gear. Consequently, the output shaft, integral with the carrier, also turns at a slower speed.

Just like all other gearboxes, the aim of planetary gearboxes is to transmit torque.

THE MAIN APPLICATION ADVANTAGES OF PRECISION PLANETARY GEARBOXES

Precision planetary gearboxes have many advantages and for this reason they are used in a wide array of industrial sectors as a very effective alternative to conventional gearboxes.

In spite of their small size, they offer high reduction ratios in presence of high transmitted torques and high loads on the output shaft.

A noteworthy fact is the forces transmitted through the gears are mutually equivalent in precision planetary gearboxes. This means that the bearings mounted on the input and output shafts can withstand loads external to the gearbox, unlike conventional devices in which the bearings must support both internal and external loads.

The result is a high-performance device because precision planetary gearboxes can sustain the same torque values in all directions.

Other benefits of planetary gearboxes include:

- Wide range of ratios resulting from the possibility of combining different planetary stages

- Coaxial input and output shafts

- Extreme application flexibility

- Compact and durable structure

- Reversibility

VARVEL PLANETARY GEARBOXES: RG SERIES PLANETARY GEARBOXES REDUCED BACKLASH

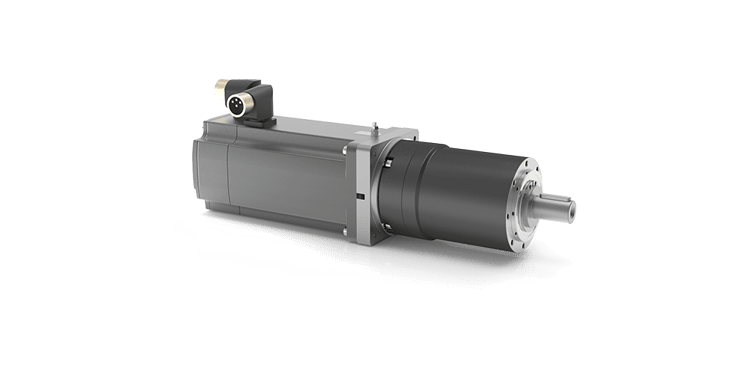

The Varvel planetary gearboxes range features the RG Series of low-backlash planetary gearboxes characterized by high speed reduction with minimum overall dimensions designed to be successfully used in all applications that require a high level of operating precision.

Available in four different sizes, the Varvel RG Series offers one or two gear pairs with gear ratios from 3:1 to 100:1 and acceleration torque up to 480 Nm.

The gearbox consists of a cylindrical steel housing on which the internal crown gear is broached, ball bearings, die-cast aluminum input flanges, heat-treated alloy steel gears and synthetic oil for lifetime gear lubrication.

This range of low backlash planetary gearboxes ensures high precision and reliability in addition to ease of installation and maintenance and high efficiency. All this in a system that is lightweight and extremely quiet during operation.

The Varvel RG Series low backlash planetary gearboxes are suitable for an array of industrial applications due to the wide range of application solutions.

Equally noteworthy is the coupling hub that Varvel has developed for the connection between gearboxes and motors (IEC, NEMA, BRUSHLESS, STEPPER). This flexible solution is an interesting alternative to the key coupling and does not increase the overall dimensions of the gearmotor.

To date, various types of motors can be installed simply by changing the connection flange. More than one hundred servomotor flanges designed for installation on Varvel gearboxes are available for installation on Varvel precision planetary gearboxes.

Get in touch with the Varvel experts for your consultation or a free estimate now.