Do you have the store full of spare parts and you break the only gearbox that you dont' have stocks? Here is the solution for you!

Do yout customers need different gearboxes to connect to different engine and you have to design a special production to satisfy everyone?

Have you ever heard of the flexible coupling?

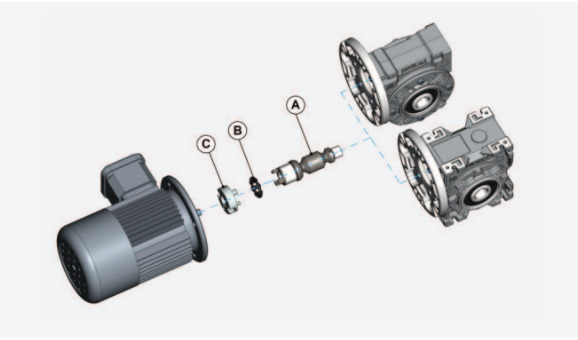

Varvel find the solution to customize the gearbox without creating obstacle in the machinery and in the store, and to allow its application to different engines. An innovative, intellingent technology allows you to keep in stock kits that can be assembled in just a few minutes to obtain a complete and ready gearbox. This kits contain all the most important components of a gearbox, squadre flanges and elastic motor coupling of different sizes that can be replaced to obtain connection with different engine shafts, thus allowing to have few problems but excellent performance.

Inside each gearbox there are gears that reduce the input speed for the recuction ratio and multiply the output torque of the eletric motor to satisfy the client application.

Combination of variables to have the perfect gearbox

The Varvel worm gearbox is completely closed and it is already designed with lubrication and to be connected to an eletric motor and to a customer's machine. The variables that you have to considered when you chose a worm gearbox are:

- the greatness

- the reduction ratio

- the diameter of the slow hole (depending on the size of the gearbox, there are holes with different diameters)

- the type of the input engine.

This means a lot of combinations, so, a lot of different gearboxes in your store, or at the distributor or in the production factory, since the market demands may require reducers with these variables mixed in various combination. Most of the worm gearboxes are sold without an eletrci motor applied, and the possibility to combining them with engines of different sizes and types would be really very advantageous.

Varvel solution: the elastic motor coupling

In 2003 Varvel designed a pressure die cast flexible coupling kit, that can connect different engines to the same gearbox (worm gearboxes, helical gearboxes, inline helical gearboxes...). It is a component that allows you to apply different types of motors to the gearbox.

It is mounted on the correct gearbox size and allows to connect different motors. This is possible because the Varvel worm gearboxes have a universal wormshaft, on wich it is possible to apply any type of engines, simply change the coupling kit for that dimension.

Varvel designed another saving in space and components, thanks to the square flanges for servomotors (to other information you can read Custom and modular square flanges). So, in case of breakages or problems the coupling kit or the flange kit can be replaced, and their replacement is very simple, without changing the reducer. They are very useful technologies for end users, as they do not need very expensive financial investments in case of problems with these pieces. Moreover, they can be assembled in very short time on different types of engines, thanks to the replacement of these kits. Varvel, its branch and its distribution network can quickly provide support thanks to the modularity of the gearboxes.

This innovation is a very important redesign work that allowed to clear the store and change the philosophy with which we rely on a speed reducer, the possibility to apply these components inside the gearbox does not increase the overall dimensions and makes it simple fault management.

The Varvel elastic coupling is the only one that must be positioned inside the gearbox without increasing its overall dimensions. It is the only clamp flexible coupling that directly connects an electric motor with a gearbox in an unchanged axial size, and with some advantages like the reduction of the coupling clearance. In fact, thanks to this replaceable component it is enough to have only one reducer for reduction ratio, and you will have:

- One gearbox only for each reduction ratio

- Greater flexibility

- Increased stock rotation

- Elimination of fretting corrosion between key and keyway

- Gearbox / motor connection with zero backlash

- Allowed angular misalignment 1° max

- High torsional rigidity

- High vibration damping

Unrivaled efficiency

This solution has offered great satisfaction for 10 years now. The success of the coupling is also due to the ability to decouple the standard magazine gearbox from the motor flange and from the electric motor. Geometrically with Vavel products is possible to do everything, install bigger or smaller motors, obviously choosing the right combination of power by selecting from the catalog, or with the VARsize section in our website.

Therefore the flexible coupling poses a great technical advantage, performance and stock advantage.